High voltage technology is a crucial element in a variety of applications in the medical, commercial/industrial, defense, and research sectors. Dielectric Sciences, Inc. (DSI) an HVT Group company, is a world leader in high voltage insulation system design and manufacturing.

Using established engineering practices and years of empirical experience, our team applies our expertise to meeting the challenges presented by our clients with the highest level of design, manufacturing, and testing solutions.

Custom Products & Designs

DSI provides many high voltage products that are standard across a range of applications in various sectors. Most of our standard products were created to provide a custom solution. The need for customization is ongoing, meeting challenges and instances where slight modifications are necessary to improve safety or performance.

Though our catalog carries almost 1,000 designs, our tried and true approach is to produce the best and most efficient solution to each situation, using a customized approach and suggesting our standard products whenever they are the right fit. Our team has the expertise to use existing, proven, and readily accessible components to give you the solution best suited to your application.

Custom Design Case Study

An example of how a custom design solution became a standard product used by our customers is the development of specialized X-ray cables and assemblies. The three phase motors commonly used on rotating anode X-ray tubes include characteristics like high voltage motor stator and PWM control using three-conductor X-ray cable at 440 volts, but fluctuating up to 75 kilo-volts or higher. Up until recently, standard three-wire cathode cables were adequate for the task.

DSI research revealed that one of the unexpected consequences of upgrading SCR drive systems with faster switches and faster pulse rise times has the effect of converting the transmission line of the cable into nearly double the 440 voltage at the stator end of the cable. This is especially common whenever cables exceed 50 feet in length. As a consequence, due to corona damage, cable insulation breakdown between the conductors can occur within a matter of months.

Advantages, Options, and Applications

Since 1970, DSI has built its reputation as a full service provider of custom high voltage solutions in response to an increased need for top-level HV connecting cables. We apply our expert, empirical knowledge and experience with proven engineering practices to solve the various HV cable, connector, and assembly issues presented by our clients. The custom solutions we provide include:

- Design

- Manufacture

- Testing

DSI’s standard and customized services meet an array of needs of our clients in a variety of application instances, including:

- HV Wire and Cable

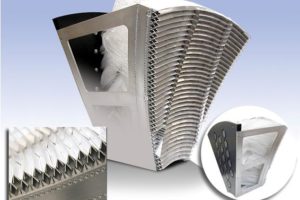

- Cast Products: Tube Shields, Insulators, Transformers, Potting

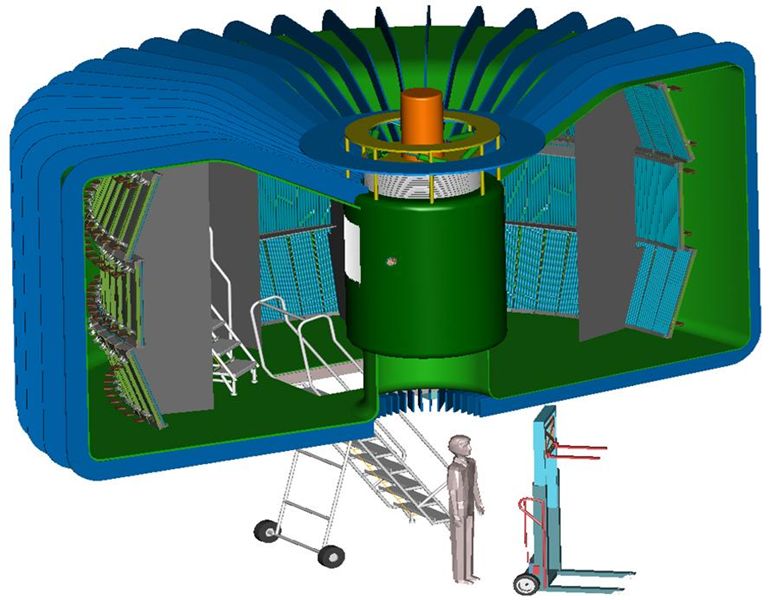

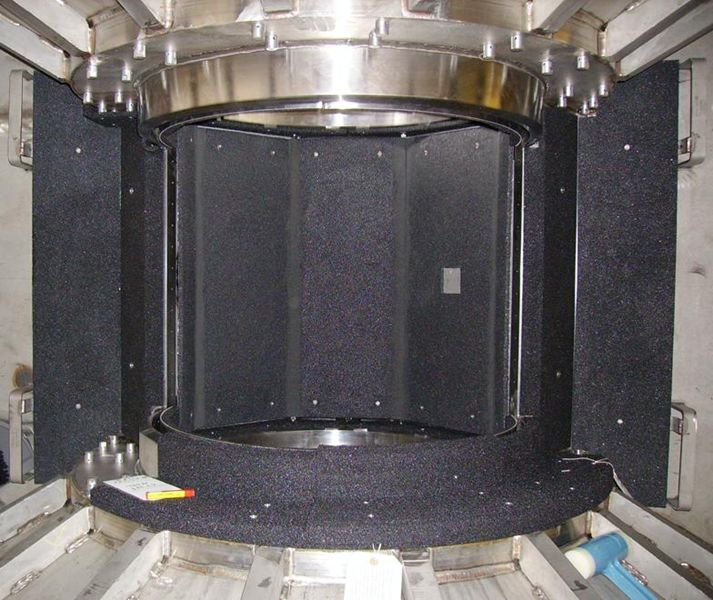

- Neutron Scattering Products: Neutron Detectors and ZHIP Mix

Dielectric Sciences’ personnel and facilities are registered with and adhere to standards outlined in ISO 9001:2008, retaining full accreditation. To learn more about our custom products and design solutions, contact us or request a quote from one of our experts for your project.